UNBEATABLE

ECO-BALANCE

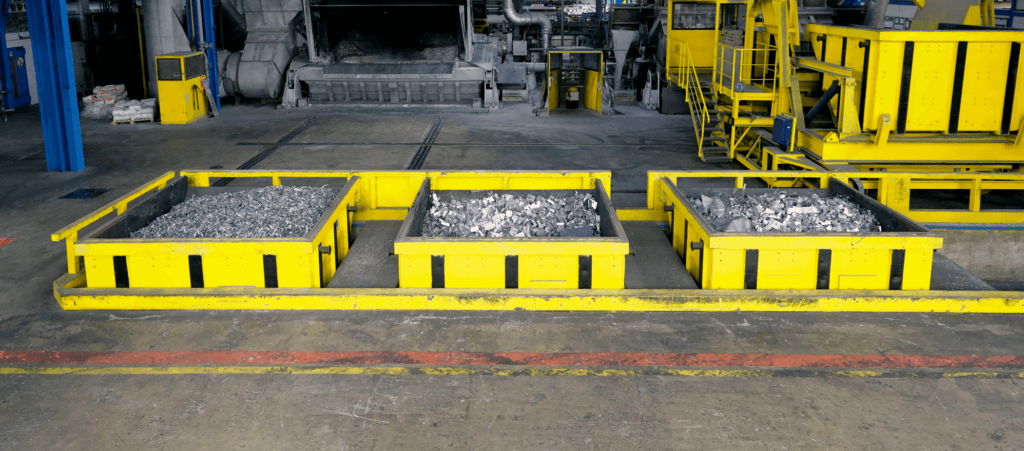

Aluminum recycling

Aluminum belongs to the light metal group and is the most common metal in the earth’s crust. Aluminum’s uses are incredibly versatile and it is almost completely recyclable. Three-quarters of all aluminum ever produced (since the 1880s) is still in productive use.

Sustainability is part of our DNA. We have extensively specialized in the processing of secondary aluminum for over 30 years. We can recycle aluminum almost as often as we want.

Thanks to our high level of expertise and many years of experience, we are able to melt a wide variety of forms of secondary aluminum with extremely low material losses while continuing to meet our customers‘ highest quality requirements.

Since 2022, we have been using electricity from 100% renewable energy sources. As a result, the CO2e footprint of the aluminum alloys we produce is unbeatable.

CO2e emissions per metric ton of produced aluminium

| 0,1* Only possible with LEICHTMETALL | |

|---|---|

| 2 European market leader | |

| 4 – 6 European competition |

*Scope 1-2.

LEICHTMETALL completes the raw material cycle

We turn scrap into a recyclable material. Not only by purchasing pre-consumer and post-consumer scrap (secondary aluminum or mixed scrap), but also during our processing: Our process scrap is free of any impurities such as lubricants or emulsions. The scrap from this process is immediately returned to the metal cycle.

Thanks to our continuously evolving casting equipment, we are able to further optimize our product range and our casting process. These optimized production methods minimize process scrap and also prevent any unnecessary reworking of our billets, thereby conserving additional resources.

In some cases, the use of primary aluminum is unavoidable. Again, in this respect, we also act in a way that conserves resources as much as possible and therefore increasingly buy “low-carbon prime aluminum”, which is primarily produced with renewable energies and a significantly lower CO2e footprint.

We are responsible!

Our heart beats green and that is why we regularly put our environmental performance to the test. We bear equal responsibility towards our employees, suppliers, customers and our environment. This is why we produce in an environmentally friendly manner, with low exhaust emissions that are significantly below the statutory emission values. Our intelligent metal cycle also conserves resources. Therefore, our own standards make us a reliable and sustainable partner.

We are in constant contact with our suppliers regarding the procurement of external scrap. By increasing the purchase and use of “End of Waste” scrap, we actively promote the idea of sustainability among our suppliers. In this way, we are helping to ensure that our high standards also lead to a change in thinking in the supply chain.

With us, employees can find:

- A job with a secure future

- Above standard pay

- Very high occupational safety levels

- Excellent development and promotion opportunities

Sustainability – How we achieve our goals

- 100% green electricity

- Responsible use of raw materials

- Increased use of end-of-waste products

- 30 years of core competence in aluminum recycling

- Promoting regional supply chains

- ASI Performance Standard as of

October 2022

- Efficient energy use

- Minimization of waste, exhaust gases and emissions

- Long-time member of VEA and

REGINEE of VE

Aluminum alloys for generations

The usually very long service life is one significant advantage of aluminum. It is not uncommon for the material to be in use for decades before it is returned to the raw material cycle. The longevity of aluminum products is closely linked to the useful life of their applications in buildings, aircraft or vehicles. At the end of its useful life, we can remanufacture aluminum into a valuable raw material for new products with a fraction of the originally required energy. Aluminum is not consumed; it is used. It provides benefits for generations.

Our certifications